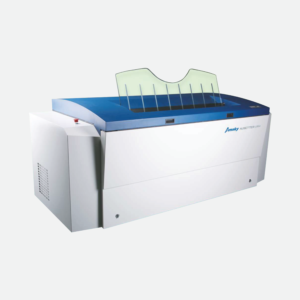

HY Automatic CTP Processor Model: HY-PST-900 IV

| Product Features | |

|---|---|

| Control System | Sophisticated control systems and anti-strong-acid material, stable and reliable |

| Control Interface | Touch screen control |

| Design | Immersed design to stabilize the screen dot quality |

| Temperature Control | Accurate developing time and temperature control, accuracy ±0.5°C |

| Washing System | Dual brushes and water washing design to ensure no residence image on the plate |

| Temperature System | Constant developing and drying temperature system to reduce the cost |

| Replenishment System | Precise automatic complement system to reduce developer loss and oxidation, extend service life |

| Gum Coating | Roller extrusion method for even coating, adjustable quantity |

| Alarm Function | Error detection for roller driving, temperature, circulating and replenishing |

| Compatibility | Can be incorporated with different brands CTP for online or offline operations |

| Basic Specifications | |

|---|---|

| Model | HY-PST-900IV |

| Plate Type | Thermal CTP plate, Gum coating, rubber roller coating type |

| Max Width | 900mm |

| Min Length | 310mm |

| Plate Thickness | 0.15~0.4mm |

| Operating Parameters | |

|---|---|

| Developing Temperature | 18-45°C |

| Developing Time | 12-45 seconds |

| Washing Speed | 430-2260mm/min |

| Developer Replenishing Speed | 1-300ml/min |

| Brush Speed | 50-150 rpm |

| Capacity & Cooling | |

|---|---|

| Capacity of Developer Bath | 31 Liters |

| Capacity of Washing Bath | 20L/fresh water/recycling water |

| Developer Cooling | Chiller unit system |

| Power Requirements | |

|---|---|

| Electrical Requirement | Single phase 220V +/- 10% 50/60Hz |

| Power | 3.5KW |

| Physical Specifications | |

|---|---|

| Machine Dimension | 2595×1320×1123mm |

| Weight | 400KG |

| Packaging Specifications-PS | 1496×1496×1248mm |

| Operation Area | 3300×4850mm |